This World Day for Safety and Health, Let’s Talk About How Computer Vision Can Ensure Occupational Health and Safety Every Day

After this last year, the world is focused on emerging from the pandemic, a healthier, safer place to live and work. World Day for Safety and Health at Work is today, 28 April, and it promotes the prevention of occupational accidents and diseases globally. It is an awareness-raising campaign intended to focus international attention on the magnitude of the problem and on how promoting and creating a safety and health culture can help reduce the number of work-related deaths and injuries.

Ensuring workplace safety can be extremely challenging. From making sure that workers wear the correct protective equipment to monitoring the entire workplace environment for safety risks, there are numerous ways that computer vision systems can assist employers in keeping employees healthy and safe. Workplace safety is everyone’s responsibility. It is estimated that a worker is injured on the job every 7 seconds–a pretty astounding number! With the help of computer vision and machine learning, businesses can not only decrease the human cost of workplace safety violations but they can also mitigate the costly financial repercussions of injuries through prevention and early detection.

Ways Computer Vision AI Can Be Applied to Mitigate Workplace Risk

Video cameras combined with the latest computer vision technology offer unblinking, objective sources for accurate monitoring of workplace health and safety compliance. Remote capabilities for continuous detection of risks also offer ways to monitor dangerous environments without risking human safety. By combining multiple camera angles with accurate computer vision models, employers are able to track all instances of noncompliance and automate alerts for corrective action in real time–saving valuable resources and preventing harm.

1. Zone-Based Safety Monitoring: Equipment & Hazard Risks

Slips, trips and falls account for 26% of workplace injuries and are completely preventable. Computer vision solutions enable the detection of hazards that often go unnoticed and inform proactive inspections and interventions. Cameras can also monitor and track heavy equipment use to ensure correct protocol is being followed. In instances where non-visible hazards, like VOC gas, can be a threat to worker safety, infrared cameras and machine learning models can be trained to detect gas leaks and automatically trigger alerts including the location and severity of the leaks.

2. Employee Ergonomics Awareness Training: Movement & Behavior Correction

Injury from overexertion and repetitive movement, like lifting, is the number one cause of injury resulting in a missing work day, accounting for 34% of all reported worker’s compensation cases. Computer vision systems can be trained to recognize correct physical form for lifting heavy objects and alert trainers when employees are in need of retraining. Models can also be trained to detect if employees are wearing protective gear like work back braces which may, or may not, be mandatory on the jobsite and help to prevent injury.

Computer vision models can be trained to recognize correct and incorrect lifting techniques to assist managers in employee training. In this image incorrect form is annotated with feature points.

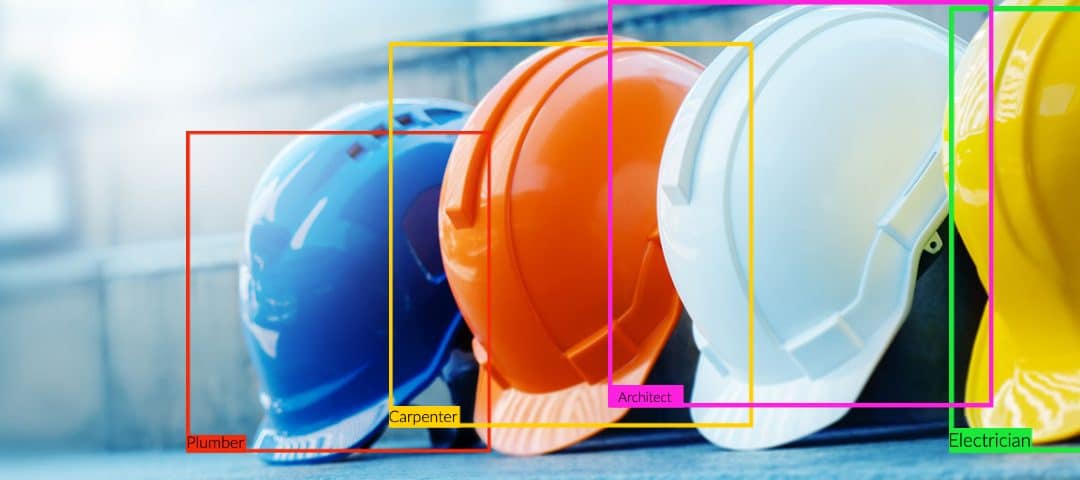

3. Personal Protective Equipment (PPE) Detection: COVID-19 & General Safety Compliance

With the onset of COVID-19, safety and health protocols have entered a new era. Most public places require masks for employees and patrons alike, and businesses need a safe and noninvasive way to monitor public space. Computer vision models can be trained to detect different PPE items, monitor social distancing and occupancy. PPE detection can be extended to include protective clothing, helmets, goggles, or other garments or equipment designed to protect the wearer’s body from injury or infection.